CSLM-250

SLM type Metal 3D Printer

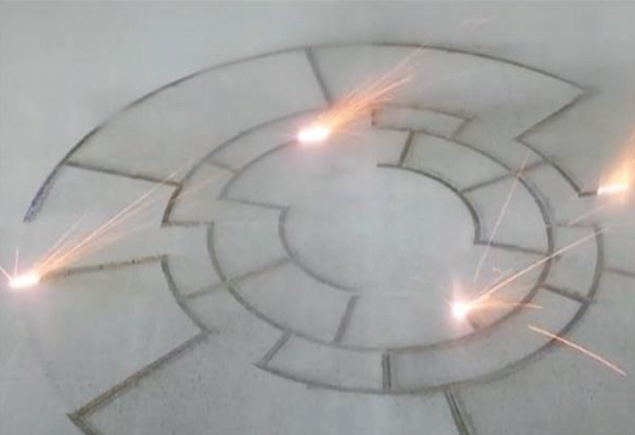

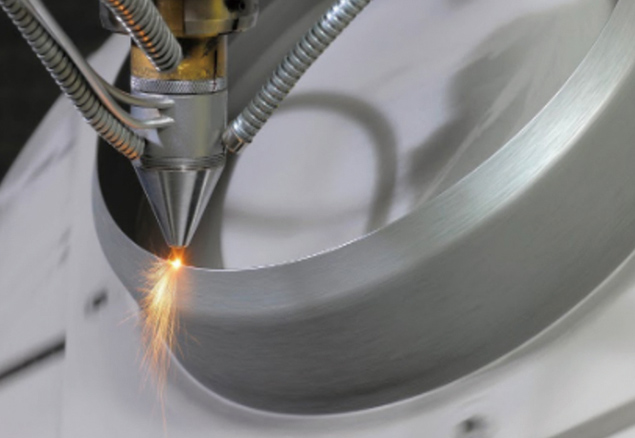

It is SLM-type 3D printer that examines metal powder with 400W fiber laser for melting, having mechanical characteristics similar to general metal manufacturing method.By checking the failure while laminating materials, it can be quickly expanded to overall manufacturing industry.

High

durability

Max. torque

8.36N*M

Improved intensity

of component

CAD data

conversion software

Two-way dual O2

monitoring device

High

accuracy

Metal 3D Printer

It uses high-output servomotor having high durability and maximum torque of 8.36N*M to withstand 200 kg payload.

By using the linear scale having 1 ㎛ resolution, 0.02 mm unit scale and the encoder with +/- 0.15 nm error, it can provide high accuracy while laminating. In addition, work status and internal/external environment can be managed conveniently in real-time.

By controlling oxygen amount to below 0.1% while driving, it has improved intensity of the component requiring high chemical purity.

By using the linear scale having 1 ㎛ resolution, 0.02 mm unit scale and the encoder with +/- 0.15 nm error, it can provide high accuracy while laminating. In addition, work status and internal/external environment can be managed conveniently in real-time.

By controlling oxygen amount to below 0.1% while driving, it has improved intensity of the component requiring high chemical purity.

Product Specifications

Move left and right with your hand.

| System | Category | Specification |

|---|---|---|

| Machine | Size Building Volume Stack Thickness Z-axis Accuracy Procress Gas Powder feeder Stroke |

990 x 2,040 x 2,015 250 x 250x 250mm 20~100㎛ ±3㎛ Nitrogen or Argon 540mm |

| Optic | Laser Output Power Laser Wavelength Beam Spot Beam Quality Scanner Positioning |

400W 1,075㎚ 70 ~ 150㎛ M2 < 1.1 10m/s |

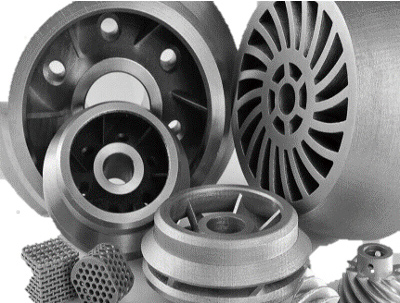

Application field for metal 3D printer

Due to restriction in material and facility while using 3D printing technology, application range in metal area is quite restrictive.

As the demand for metal parts is increasing, application is being expanded to automotive sector, aerospace sector, medical sector, cultural asset restoration, and robot nuclear power, which is expected to be used universally like plastic material in near future.

As the demand for metal parts is increasing, application is being expanded to automotive sector, aerospace sector, medical sector, cultural asset restoration, and robot nuclear power, which is expected to be used universally like plastic material in near future.

Medical

Flight

Robot

Vehicle